Building a sustainable future, one seed at a time

Delivering the cleanest and most efficient technology for optimal seed decontamination.

Contaminated seeds, a persistent challenge? We deliver the solution.

Hemeris develops and operates cold plasma decontamination technology tailored for the seed industry’s most stringent requirements. Our dry, residue-free treatment effectively targets key bacterial and fungal pathogens on seeds such as carrot, bean, pea, and lettuce, with no impact on germination rates.

| Crop | Pathogens we successfully decontaminated |

|---|---|

| Bean | Xanthomonas, Pseudomonas |

| Carrot | Xanthomonas, Alternaria |

| Radish | Xanthomonas, Pseudomonas |

| Brassica | Xanthomonas, Pseudomonas, Alternaria |

| Beetroot, Swiss chard | Phoma, Cercospora, Pseudomonas |

| Cucurbites | Pseudomonas, Xanthomonas |

| Lettuce, wild rocket | Pseudomonas, Fusarium |

| Wheat | Fusarium |

| Parsley | Septoria |

| Corn salad | Phoma |

| Tomato | Pseudomonas |

Why we use cold plasma, and nothing else

Chemical-free, non-thermal, and residue-free: cold plasma is the cleanest and most effective solution for seed decontamination.

At atmospheric pressure, plasma energy disrupts pathogens without damaging the seed structure or reducing germination potential.

This is a cutting-edge alternative to conventional chemical fungicides, only using air and electricity.

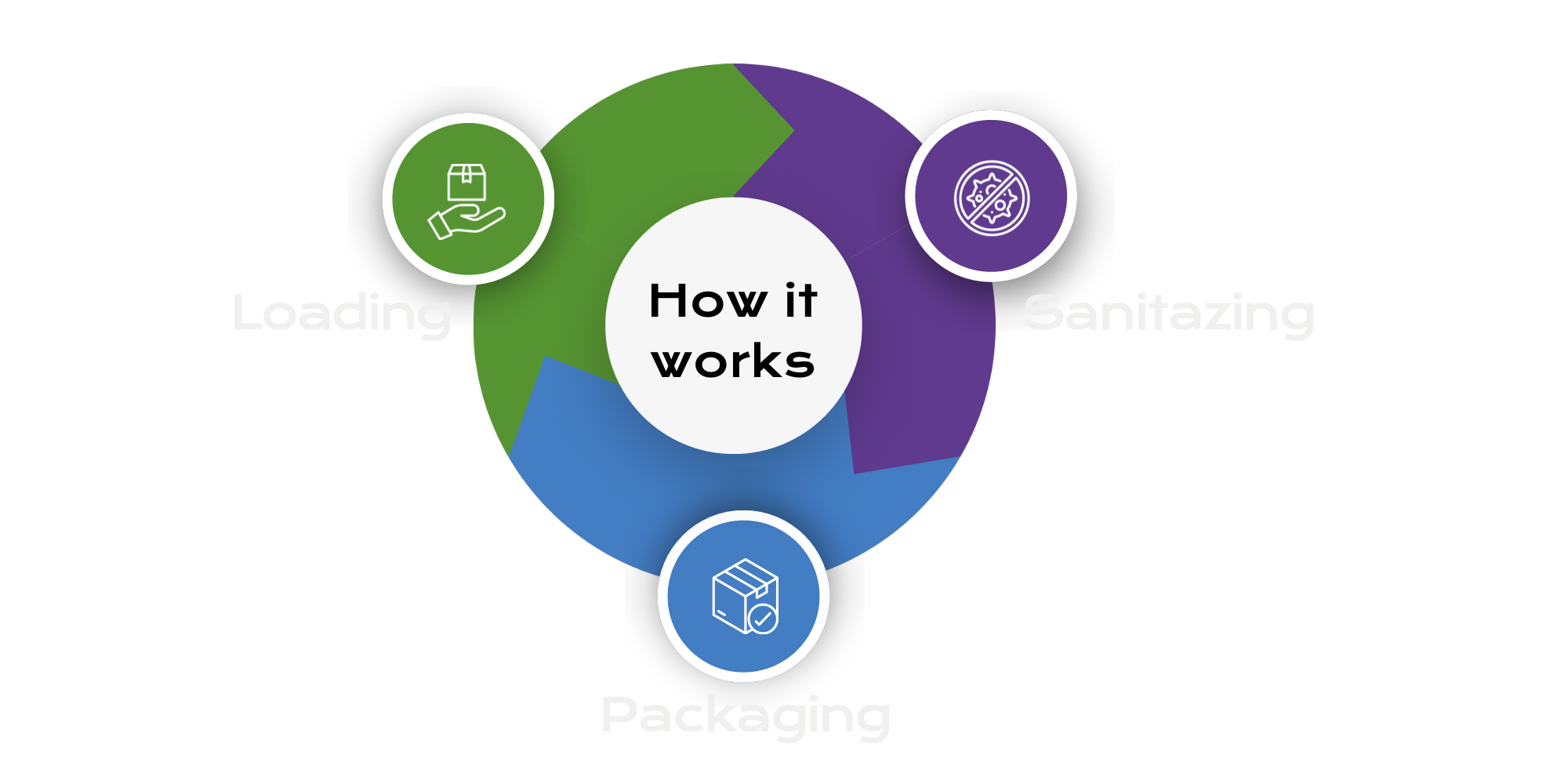

3 steps. 0 chemicals

Our process is simple, fast, and effective:

- 150 kg batches of seeds are loaded

- They pass through a controlled plasma exposure tunnel

- We analyse decontamination and germination before communicating results.

Seeds are clean and ready to be collected packed or sown

Our machines operate continuously and are monitored in real time by embedded control systems.

Every step is designed to preserve biological quality while ensuring complete decontamination.

We eradicate all pathogens on

What We Do

This is a cutting-edge alternative to conventional fungicides and chemical treatment, with no environmental waste. Unlike chemical methods, it leaves no harmful residues, prevents seepage into

the soil, preserves the natural soil microbiome, laying the foundation for healthier crops and sustainable agriculture.

Our Services

We decontaminate up to

We deliver clean seeds

Hemeris offers a professional, in-house treatment service using our proprietary cold plasma technology.

We handle your seeds at our facility, process them with our team and tools, and send them back, clean and ready.

This is a turnkey service : not a prototype, not a pilot.

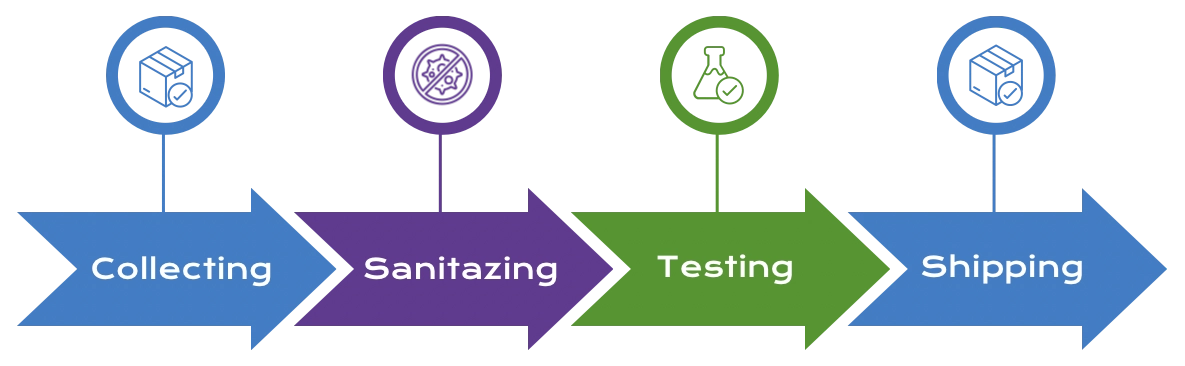

A streamlined 4-steps workflow

- You ship your seed lots to our facility

- We process them with our industrial plasma line

- Our quality control team analyses the seeds

- We send your seeds back

Custom protocols can be developed depending on seed type, size, and sanitary needs. We ensure full traceability, control, and consistency

Cleaner seeds, simpler logistics, safer operations

- Eliminate chemicals

- Reduce post-treatment steps (drying, rinsing)

- Enhance brand value with sustainable practices

- Rely on a partner that guarantees results and timelines

We built this service for seed professionals who need reliability, not experiments.

Our team

Deeptech meets seed expertise

Hemeris is a team of engineers, biologists, and physicists united by one goal: creating a clean, industrial alternative to chemical decontamination.

Each core team member brings deep R&D expertise and hands-on experience, from plasma dynamics to microbiology and machine control.

“We didn’t just build a machine, we built a working, scalable solution.”

— Olivier, CTO

© Hemeris

Our Labs

Rooted in science

Hemeris was born out of 3 years of research and lab testing.

We continue to operate in partnership with external labs and seed biology experts to test, validate, and refine each protocol.

We develop species-specific plasma exposures to ensure both efficiency and seed safety.

We also build and use AI tools to further our expertise and optimize tasks.

We don’t guess : we measure.

Our Development

From prototype to production

After a successful pilot phase, we launched our industrial treatment facility in 2025.

Today, we operate our own equipment at scale, with growing throughput and client demand.

We are already partnering with large seed producers and plan to open capacity to more clients across Europe.

Our team

CEO

Born into a family of market gardeners in the Drôme region, Steven Deves-Girain drew inspiration from his roots to found Hemeris in 2021.

His goal: to transform agriculture and the agri-food industry by reducing their reliance on chemicals.

A graduate of the ESSEC – CentraleSupélec Paris dual degree program, he has in-depth expertise in atmospheric-pressure cold plasmas. Building on this experience, he is leading Hemeris to the forefront of innovation in seed treatment.

Plasma team

Olivier Battaglini, our electronics engineer and a graduate of CentraleSupélec. In addition to playing a key role in our R&D, he is the master of electronic development: Olivier is the mind behind the firmware and software of our seed treatment equipment.

Chih-Min Chen, our postdoctoral researcher specialized in plasma decontamination. With deep expertise gained during his PhD on atmospheric-pressure cold plasmas for the treatment of biological substrates, he conducts plasma experiments to develop and enhance our technology, delivering innovative solutions.

Specialist in the application of cold plasma to seeds